If you’ve ever shopped for screws, nuts, or bolts, you’ve probably noticed numbers like 8.8, 10.9, or Grade 5 stamped onto their heads. These numbers aren’t random; they indicate the strength and material properties of the fastener. Understanding fastener grades is crucial for ensuring you use the right screw for the right job – whether you’re working on an aircraft, a car, or a DIY home project.

Why Fastener Grades Matter

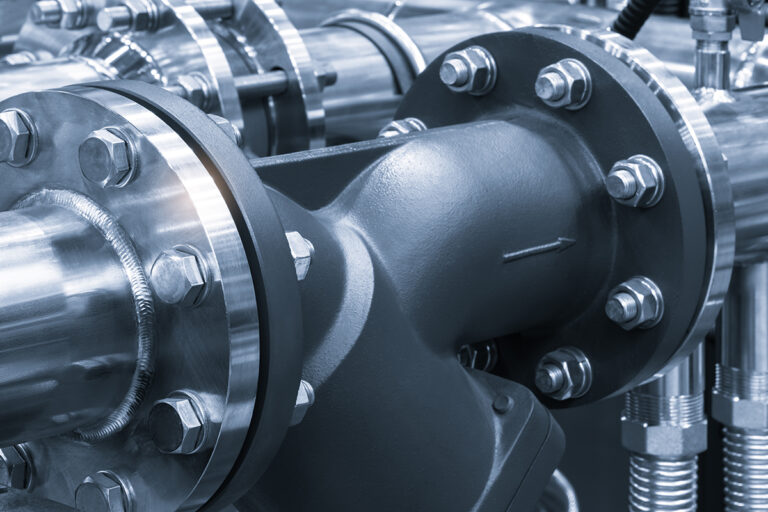

Fasteners are responsible for holding everything together, from bridges and airplanes to furniture and machinery. Using the wrong grade can lead to structural failures, which can be costly and even dangerous. The grade system helps engineers, mechanics, and builders select the correct fasteners based on strength, durability, and application needs.

Types of Fastener Grades

The Metric ISO (International Organisation for Standardisation) grading system and the Imperial SAE (Society of Automotive Engineers) grading system are two distinct methods for classifying fastener strength and mechanical properties.

The ISO metric system uses numerical property class, such as 4.6, 8.8, 10.9, and 12.9, where the first number represents the bolt’s tensile strength in megapascals (MPa) divided by 100, and the second number represents the yield strength as a ratio of tensile strength. For example, a 10.9 bolt has a tensile strength of 1,000 MPa and a yield strength of 900 MPa.

In contrast, the SAE imperial system classifies fasteners using grades (Grade 2, Grade 5, and Grade 8) and head markings (radial lines), with tensile and yield strengths measured in pounds per square inch (PSI). A Grade 8 bolt, for example, has a tensile strength of 150,000 PSI and a yield strength of 130,000 PSI.

While the ISO system is widely used internationally, the SAE system is primarily used in North America, particularly in the automotive and heavy machinery industries.

How to Read Metric Fastener Grades

You’ll commonly see numbers like 4.6, 8.8, 10.9, and 12.9 stamped on metric fasteners. The numbers in metric bolt grades represent two key properties:

Tensile Strength (MPa) – The first number, multiplied by 100, gives the approximate tensile strength in megapascals (MPa).

Yield Strength Ratio – The second number represents the ratio of yield strength to tensile strength.

For example, in a 10.9 fastener:

- The first number (10) means the bolt has a tensile strength of 1,000 MPa.

- The second number (0.9) means its yield strength is 90% of its tensile strength (or 900 MPa).

Common Metric Fastener Grades & Strengths

Metric Coatings & Treatments

Metric fasteners often come with coatings like zinc plating (for corrosion resistance) or black oxide (for a sleek, rust resistant finish).

Understanding Imperial (SAE) Fastener Grades

Imperial fasteners follow the SAE (Society of Automotive Engineers) grading system, which uses words like Grade 2, Grade 5, and Grade 8 instead of decimal numbers. Unlike metric fasteners, SAE fasteners are identified by head markings consisting of radial lines. The more lines, the stronger the bolt.

Common SAE Fastener Grades & Their Strengths

SAE Coatings & Treatments

Like metric fasteners, SAE fasteners are available with zinc plating, galvanised coatings, or heat treated finishes for added durability.

Comparing Metric vs SAE Fasteners

When working with fasteners, it’s crucial to use the correct type – mixing metric and SAE fasteners can lead to incorrect fits and structural weaknesses. Here’s how they compare:

Choosing the Right Fastener for Your Project

Selecting the correct fastener grade depends on several factors:

- Load Requirements: Higher grades are needed for heavy loads and high-stress applications.

- Material Compatibility: Ensure your bolt is compatible with the material it’s fastening to prevent galvanic corrosion.

- Environmental Conditions: Corrosion resistant coatings are essential for outdoor or marine environments.

Key Takeaways

- Metric fasteners use a two number class system (e.g. 10.9, where the first number x 100 = tensile strength in MPa, and the second number is the ratio of yield to tensile strength).

- Imperial fasteners use grades with radial markings (more lines = stronger fastener).

- Stainless steel fasteners focus on corrosion resistance rather than high tensile strength, though A4-80 has mechanical properties close to Grade 5 fasteners.

Understanding fastener grades is essential for selecting the right screw or bolt for the job. Whether you’re assembling furniture, working on an aircraft, or maintaining an engine, knowing what those numbers mean can prevent failures and ensure safety.

Next time you’re at the hardware store, take a closer look at those fastener markings – you’ll know exactly what they mean and why they matter!

Our team of experts are ready to assist you in choosing the most suitable security screws for your specific requirements.

Contact us today on 1800 776 565.

Secure Your Assets with Sentinel Group Security Screws.

Choose Sentinel Group Security & Customised Fastening Solutions.