In an increasing interconnected world, safeguarding valuable assets and maintaining security is of paramount importance. Security fasteners play a crucial role in preventing tampering, theft, and unauthorised access to various objects and systems. From protecting intellectual property to securing high-value equipment, these specialised fasteners provide an extra layer defence. But have you ever wondered how manufacturers produce security fasteners? In this article, we’ll explore the manufacturing process behind these tamper-proof devices and delve into the intriguing world of security technology.

Understanding the Need for Security Fasteners

Before diving into the manufacturing process, it’s important to understand why security fasteners are necessary. Common tools can easily remove standard screws and bolts, making them vulnerable to tampering or theft. Security fasteners, on the other hand, incorporate unique designs, special heads, or specific tool requirements that prevent unauthorised removal. Industries such as aerospace, defence, electronics, automotive, and even public infrastructure widely use them.

Materials Used in Security Fasteners

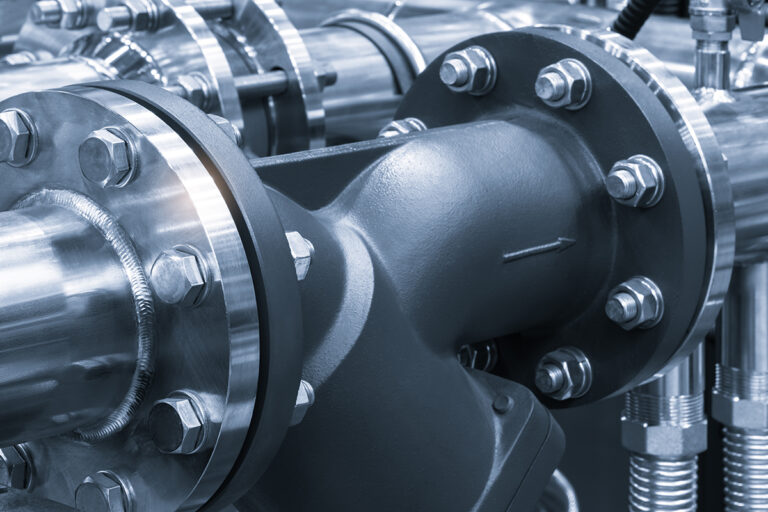

Manufacturers typically use robust and durable materials to produce security fasteners, ensuring their strength and resistance to tampering. Additionally, common materials include stainless steel, alloy steel, and high-strength carbon steel. Furthermore, these materials offer excellent corrosion resistance and are capable of withstanding extreme environments.

Manufacturing Processes

Design and Engineering: The journey of a security fastener starts with thorough design and engineering. The primary objective is to create a fastener that is challenging to remove without the designated tools. Engineers meticulously craft unique head shapes, drive systems, or unconventional grooves that deter unauthorised access.

Material Selection: Once the team finalises the design, they select the appropriate material based on the specific requirements of the application. During this stage, they consider factors such as strength, durability, corrosion resistance, and environmental conditions.

Machining: Machining is a crucial step in the manufacturing process. Modern manufacturing techniques, such as CNC (Computer Numerical Control) machining, are employed to achieve precise and intricate designs. The chosen material is shaped into the desired form, which can include Resytork, Powertork, Pentaforce, or Two-Hole heads, among others.

Heat Treatment and Finishing: After the machining process, heat treatment is often applied to enhance the hardness and strength of the fastener. Heat treatment processes like quenching and tempering are employed to achieve the desired mechanical properties. Following this, the fasteners undergo surface finishing processes, such as coating or plating, to enhance corrosion resistance and aesthetics.

Quality Assurance: Quality control is crucial in the manufacturing of security fasteners. Stringent testing procedures, including torque testing, tensile strength tests, and corrosion resistance checks, are conducted to ensure the fasteners meet the required specifications and standards.

Customisation and Tooling

You can further customise security fasteners to meet specific industry needs. By offering branding, serialisation, or unique markings on the fasteners, allowing easy identification and traceability. Tooling is also a significant aspect of security fasteners, as they require specialised tools that match the unique head designs. This helps to restrict unauthorised access and minimise the risk of tampering.

Conclusion

Security fasteners are a vital component in safeguarding valuable assets and ensuring the integrity of various systems. The manufacturing process involves meticulous design, material selection, precision machining, heat treatment, finishing, and rigorous quality control. With their unique features and tamper-proof technology, security fasteners contribute significantly to deterring theft, protecting sensitive information, and maintaining the security of critical infrastructure. As technology continues to advance, we can expect to see even more sophisticated security fasteners that will play a crucial role in the protection of our assets and systems.

Our team of experts are ready to assist you in choosing the most suitable security screws for your specific requirements.

Contact us today on 1800 776 565.

Secure Your Assets with Sentinel Group Security Screws.

Choose Sentinel Group Security & Customised Fastening Solutions.