When assembling machinery or structures, ensuring fasteners are tightened correctly is essential for safety, performance, and longevity. One critical aspect of achieving this is understanding how to calculate fastener torque. This blog will guide you through the process, providing clear steps and insights into the science behind it.

What is Torque?

Torque is the rotational force applied to an object, such as a screw or bolt. It’s typically measured in units like Newton-meters (Nm). Proper torque ensures that a fastener is tight enough to hold components securely but not tight that it risks damage or failure.

Why Is Fastener Torque Important?

Preventing Over-Tightening: Excessive torque can lead to stripped threads or deformation of the fastener.

Ensuring Proper Load Distribution: Correct torque ensures even clamping forces, reducing the risk of leaks or structural weaknesses.

Avoid Under-Tightening: Insufficient torque can result in loose fasteners, leading to operational failures.

The Basics of Torque Calculation

The simplified formula to calculate torque is:

T = k*D*P

Where:

T = Tightening Torque (Nm)

k = Torque coefficient or nut factor (dimensionless, typically between 0.15 and 0.2 for lubricated fasteners).

D = Diameter of the fastener (mm)

P = Clamping force or preload (kN)

Step-By-Step Guide to Calculating Torque

1. Determine the Clamping Force (P)

Clamping force is often specified in design requirements. If not, you can calculate it based on the tensile strength of the fastener and the percentage of preload needed.

Example: for a bolt with a tensile strength of 100,000 psi and a desired preload of 75%, calculate the force:

P = Tensile Area x Tensile Strength x Preload Percentage

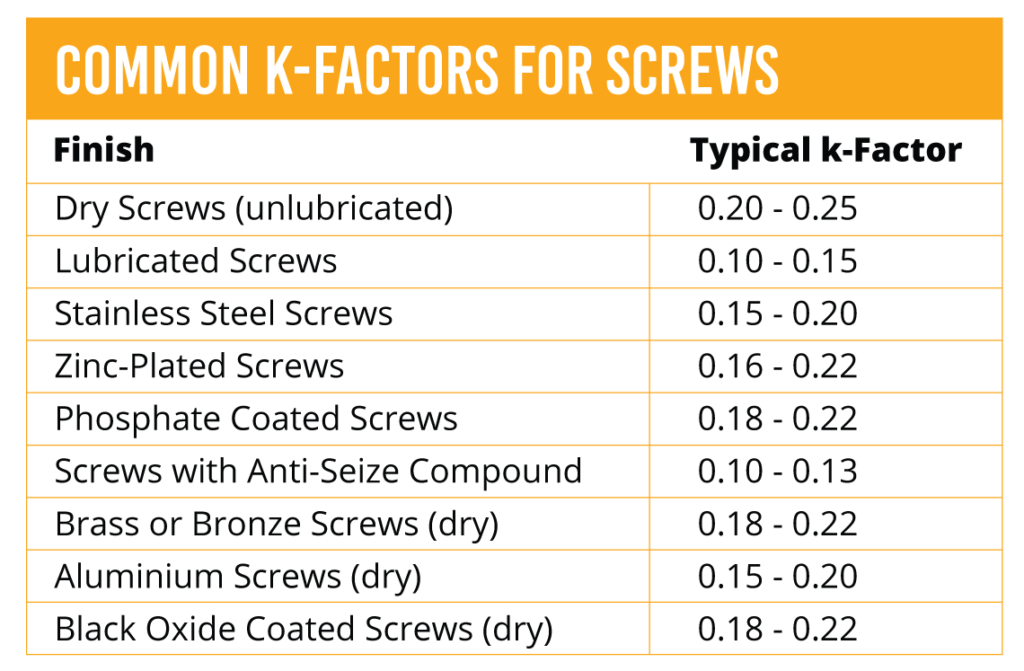

2. Find the Torque Coefficient (k)

The torque coefficient depends on the material and lubrication of the fastener. Refer to manufacturer specifications or use standard values (eg. 0.2 for dry steel, 0.15 for lubricated steel).

3. Measure or Look Up the Fastener Diameter (D)

This is the nominal diameter of the bolt or screw. Ensure you use consistent units (millimetres or inches).

4. Apply the Formula

Plug the values into the formula to calculate the torque.

Example: A lubricated bolt with a diameter of 0.02 mm and required clamping force of 20,000 kN has a torque coefficient k = 0.15. The torque is:

T = 0.15 * 0.02 * 20,000 = 60 Nm

Factors Affecting Torque Calculation

Accurately calculating and applying torque depends on several factors:

1. Lubrication

Lubrication reduces friction between the fastener and mating surface, affecting the torque coefficient k. For example:

- Dry threads have higher friction and require more torque.

- Lubricated threads allow for lower torque values to achieve the same clamping force.

2. Thread Condition

Damaged or dirty threads can increase friction, leading to inaccurate torque readings. Always clean and inspect threads before tightening.

3. Material Properties

The material of both the fastener and mating components affects friction and preload. For example:

- Stainless steel screws often have different torque coefficients than carbon steel bolts.

- Surface coatings like zinc plating can also alter friction.

4. Temperature

Thermal expansion can affect the clamping force, especially in high temperature environments. Consider using torque values adjusted for operating temperatures.

5. Dynamic Forces

Applications subject to vibration or shock loads may require additional considerations, such as thread lockers or higher preload values.

6. Calibration of Tools

Torque wrenches mush be calibrated regularly to ensure accurate torque application. Over time, wear and tear can reduce their precision.

Tips for Accurate Torque Application

Use a Torque Wrench

This ensures you apply the correct torque and prevents guesswork.

Lubricate Threads

Lubrication reduces friction and allows for more consistent torque values.

Calibrate Tools Regularly

Torque wrenches can lose accuracy over time and need periodic calibration.

Account for Dynamic Conditions

In environments with vibration or thermal expansion, use locking mechanisms like thread lockers or lock washers.

Common Mistakes to Avoid

Ignoring Friction

Always account for lubrication or surface treatments, as they significantly affect torque values.

Using Incorrect Units

Ensure all measurements are in compatible units to avoid errors.

Neglecting Safety Margins

Overestimating torque can lead to catastrophic failures. Always adhere to recommended specifications.

Glossary

Torque Coefficient (k)

Also known as the nut factor, it is a dimensionless value that accounts for the frictional forces in the threads and under the head of the fastener. It varies depending on material, lubrication, and surface conditions. Typical values range from 0.15 (lubricated fasteners) to 0.2 (dry fasteners).

Clamping Force (P)

The axial force generated when a fastener is tightened. It is responsible for holding the components together. The clamping force is calculated based on the tensile strength of the fastener and the desired preload percentage.

Torque (T)

The rotational force applied to a fastener, typically measured in Newton-meters (Nm). Torque ensures the proper clamping force is achieved without over-tightening or under-tightening.

Fastener Diameter (D)

The nominal diameter of the bolt or screw, usually measured in millimetres or inches. It is a key parameter in torque calculation.

Preload

The initial tension created in a fastener when it is tightened. Preload is critical for maintaining the joint’s integrity under operational conditions.

Lubrication

The use of oils or greases to reduce friction between the fastener and the mating surface, allowing for more accurate torque application.

Conclusion

Calculating fastener torque is a critical skill for engineers, mechanics, and DIY enthusiasts alike. Calculating fastener torque using T=kDP is a straightforward yet critical process. By understanding the formula and accounting for factors like lubrication, material properties, and thread condition, you can ensure secure and reliable fastener assemblies. Proper torque application isn’t just about precision, it’s about safety and durability.

Our team of experts are ready to assist you in choosing the most suitable security screws for your specific requirements. We’re here to help you with calculating fastener torque.

Contact us today on 1800 776 565.

Secure Your Assets with Sentinel Group Security Screws.

Choose Sentinel Group Security & Customised Fastening Solutions.