When it comes to securing critical components in industries such as aerospace, automotive, infrastructure, and defence, the integrity of fastened joints can make the difference between success and catastrophic failure. While torque is the most commonly measured variable during fastener installation, it’s actually tension – the clamping force generated in the fastener – that truly determines joint reliability.

In this article, we’ll explain the difference between torque and tension, why tension is a more accurate indicator of joint performance, the risks of relying solely on torque, and best practices for ensuring optimal tension in critical applications.

What’s the Difference? Torque vs Tension

Torque: is the rotational force applied to a screw or bolt during tightening. It’s usually measured in Newton-meters (Nm) or inch-pounds (in-lbs). Torque is easy to measure with a wrench, which is why it’s become the default standard for assembly operations.

Tension: (also called preload) is the axial force that stretches the fastener and clamps the joined components together. It’s what actually holds the joint in place. Tension is what resists the forces trying to pull the joint apart during service.

Helpful Hint: Torque is what you apply. Tension is what you get.

Why Torque Alone Can Be Misleading

While torque and tension are related, their relationship is far from consistent. That’s because friction (in the threads, under the bolt head, and between joint materials) absorbs a large percentage of the torque applied.

Typical Torque Distribution:

50% – 55%: Lost under head friction

30% – 35%: Lost to thread friction

10% – 20%: Actually converted into bolt tension

Because friction can vary dramatically due to lubrication, surface finish, coating, material type, and temperature, two identical torque readings can result in wildly different tension levels – a serious problem in high stakes applications.

Why Tension Matters More in Critical Applications

In safety-critical or performance-critical assemblies, what truly counts is the clamping force holding components together. Here’s why tension takes precedence:

1. Joint Integrity

Insufficient tension can lead to:

- Joint separation

- Vibration loosening

- Fatigue failure

- Leaks in pressurized systems

Over-tension, on the other hand, can lead to:

- Bolt yielding

- Thread stripping

- Material deformation

2. Consistent Performance Under Load

Tension maintains joint stability under dynamic loading. Critical assemblies experience shear, tensile, and bending loads that only properly tensioned fasteners can withstand.

3. Predictable Life Cycle

Bolted joints in aircraft, turbines, bridges, or chemical processing plants must perform over long periods without inspection or re-tightening. Only proper tensioning ensures such long-term reliability.

Real World Examples of Tension Failure

Space Shuttle Challenger Disaster (1986): Though not directly caused by fastener tension, the failure highlighted how thermal cycling and component separation due to insufficient clamping can have fatal consequences.

Aerospace Panel Detachments: Several aircraft incidents have traced back to improperly tensioned bolts that backed out due to vibration.

Bridge Bolt Failures: Corrosion and under-tension in structural fasteners have led to collapse or critical damage in public infrastructure.

How to Measure and Ensure Proper Tension

Since torque is not a reliable proxy for tension, critical applications often use more accurate tension verification methods:

Ultrasonic Measurement: Uses sound waves to measure the elongation of the bolt, which directly relates to tension. Highly accurate, but expensive and time consuming.

Load Indicating Washers or Direct Tension Indicating (DTI) Washers: These change shape or compress to indicate when the correct clamping force has been reached.

Tension Control Bolts: Common in structural steel applications. The spline breaks off at a calibrated tension value, ensuring consistency.

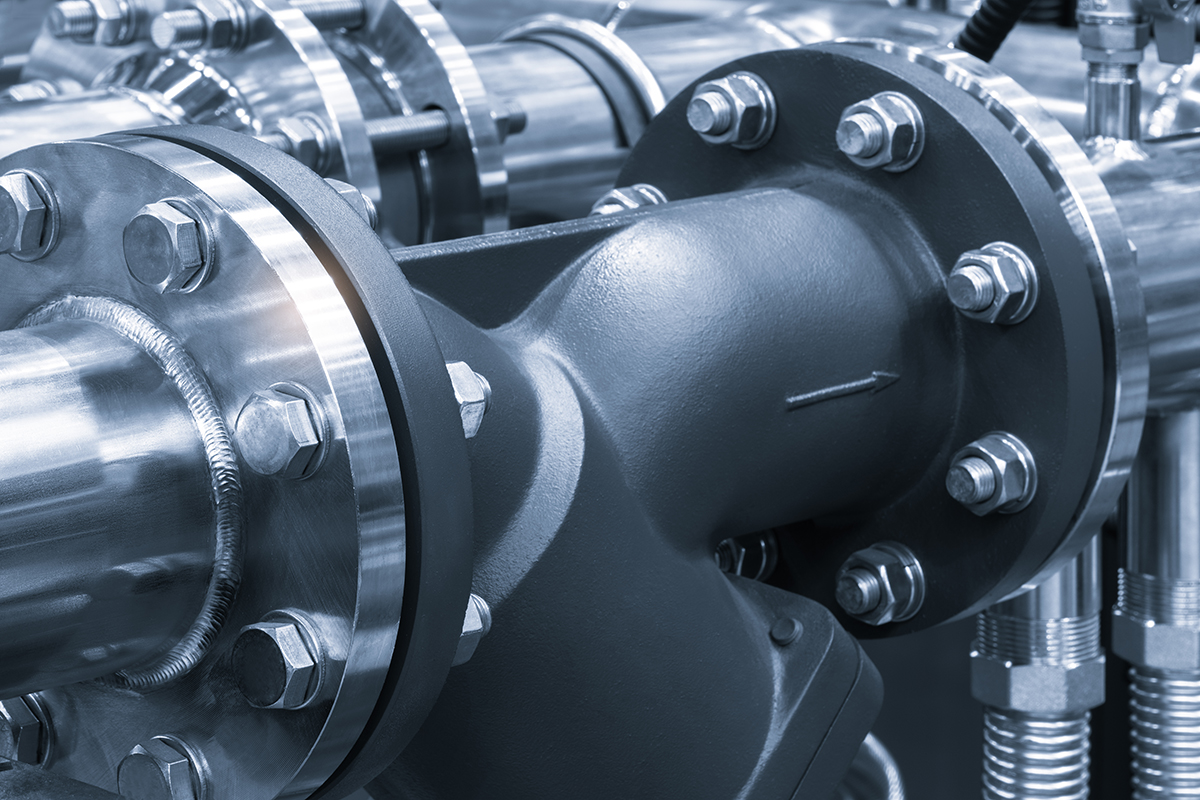

Hydraulic Bolt Tensioners: Stretch the bolt directly with hydraulic force, then the nut is run down. Used in pipelines, turbines, and underwater equipment (eg. offshore oil & gas, marine engineering, ocean exploration).

Torque + Angle Method: Applies torque, then adds a specific angle of rotation. More consistent than torque alone, but still not tension specific.

Best Practices for Fastening Critical Joints

Avoid relying solely on torque specs unless you’re in a non-critical or well controlled environment.

Use lubricants or coatings consistently to minimise friction variability.

Specify fasteners with known performance under preload, such as structural bolts, tension control bolts, or tension calibrated fasteners.

Use tension verification tools when safety, integrity, or system uptime depends on the joint.

Conclusion

In critical applications, tension is the real objective, not torque. Torque is simply a means to an end – and a highly variable one at that. Whether you’re designing aerospace systems, assembling wind turbines, or securing structural elements, understanding and controlling screw tension is essential for performance, reliability, and safety.

By focusing on accurate tension control, not just torque specs, you reduce the risk of joint failure, prolong component life, and build safer, more resilient systems.

Contact our expert team today on 1800 776 565 – we’ll help you find the perfect fastener that’s strong, secure, and certified to perform.

Secure Your Assets with Sentinel Group Security Screws.

Choose Sentinel Group Security & Customised Fastening Solutions.