In mechanical fastening, understanding the forces acting on a screw is crucial to ensure safe, strong, and long-lasting joints. Two key performance measures often reference in fastener selection are tensile strength and shear strength. While these terms are sometimes used interchangeably, they represent very different failure modes and have distinct implications in screw applications.

Read on to learn more about shear vs tensile strength, what each means, how they differ, and how they apply in real-world uses of screws.

What is Tensile Strength?

Tensile strength refers to a screw’s ability to withstand a force that attempts to pull it apart along its length. When you apply axial tension (a straight pull), the screw stretches. If the force exceeds its tensile strength, the screw will snap – typically at the root of the thread or where the minor diameter is weakest.

- Measured in: Megapascals (MPa) or pounds per square inch (psi)

- Testing Method: Pulling the screw axially in a tensile testing machine until failure

Example of tensile loading: A bolt used to clamp two plates together experiences tensile stress if the plates are being pulled apart.

What is Shear Strength?

Shear strength is the ability of a screw to resist sliding forces that try to cut it across its body. In a shear load, two opposing forces are applied across the fastener, and the screw can fail by being sliced through like a pair of scissors.

- Measured in: Megapascals (MPa) or pounds per square inch (psi)

- Typical Estimation: Shear strength is often approximated as 60% of tensile strength for carbon and alloy steels, although this varies by material and thread geometry.

Example of shear loading: A lag screw holding a heavy shelf bracket experiences shear force if the shelf tries to slide down the wall.

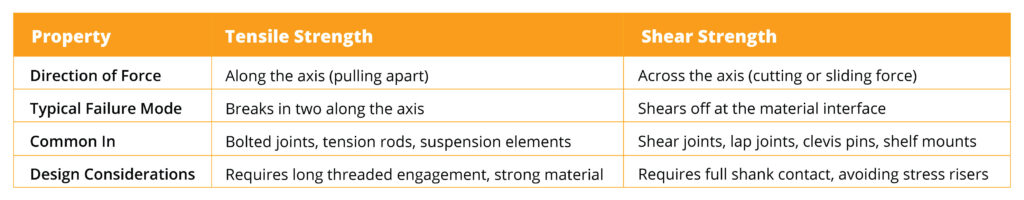

Shear vs Tensile: Key Differences

Threaded vs Unthreaded Sections in Shear Loads

In shear applications, the unthreaded shank of a screw is significantly stronger than the threaded portion. Threads act as stress concentrators, reducing the cross-sectional area and strength in shear.

That’s why engineers often specify that shear loads should occur on the unthreaded portion of a screw. If the threads lie in the shear plane, the joint is more likely to fail prematurely.

Screw Selection Based on Load Type

When choosing screws for an application, it’s important to know whether tensile or shear loads, or a combination of both, will dominate.

If Tensile Loads Dominate:

- Choose high tensile fasteners (e.g. Class 8.8, 10.9, or 12.9)

- Ensure sufficient thread engagement

- Use washers or spacers to distribute load evenly

If Shear Loads Dominate:

- Prefer shoulder bolts or screws with long unthreaded shanks

- Use double shear joints if possible (distributes force across two planes)

- Ensure shear force acts across the full cross-section

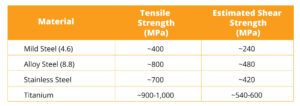

Material Considerations

The material composition of screws plays a big role in determining both tensile and shear strength.

Always refer to manufacturer datasheets.

How to Avoid Failure

Common Mistakes:

- Using screws with insufficient tensile capacity for axial loads

- Allowing shear forces to act on threaded sections

- Ignoring combined loading (many applications involve both)

Tips:

Design joints to avoid prying, bending, or off-axis loads

In shear joints, ensure a tight fit in the hole to prevent movement

Use torque specifications appropriate for the screw size and material

Combined Shear and Tension Forces

In many real world applications, screws are subject to both shear and tensile forces at the same time. For example, a screw holding a bracket may be pulled outward (tension) while also experiencing sideways force (shear) from the weight it supports. When both types of stress are present, it’s important to consider their combined effect rather than evaluating each one in isolation.

Engineers use established methods to assess whether a fastener can handle this mixed loading safely. Essentially, they calculate the total stress by factoring in the effects of both pulling and cutting forces together. This ensures that even if neither the tension nor the shear alone is high enough to cause failure, their combined influence doesn’t exceed the screw’s overall strength.

Conclusion

Understanding the difference between shear vs tensile strength is essential for selecting the right screw and designing robust joints. Whether you’re installing structural bolts in a steel frame or choosing the right wood screw for a furniture joint, knowing how forces act on fasteners will help you prevent failures and build stronger, safer assemblies.

Contact our expert team today on 1800 776 565 – we’ll help you find the perfect fastener that’s strong, secure, and certified to perform.

Secure Your Assets with Sentinel Group Security Screws.

Choose Sentinel Group Security & Customised Fastening Solutions.